Tel: 0129-4001010 Phone: +91 730 321 5033

Email: cs@absoluteveritas.com

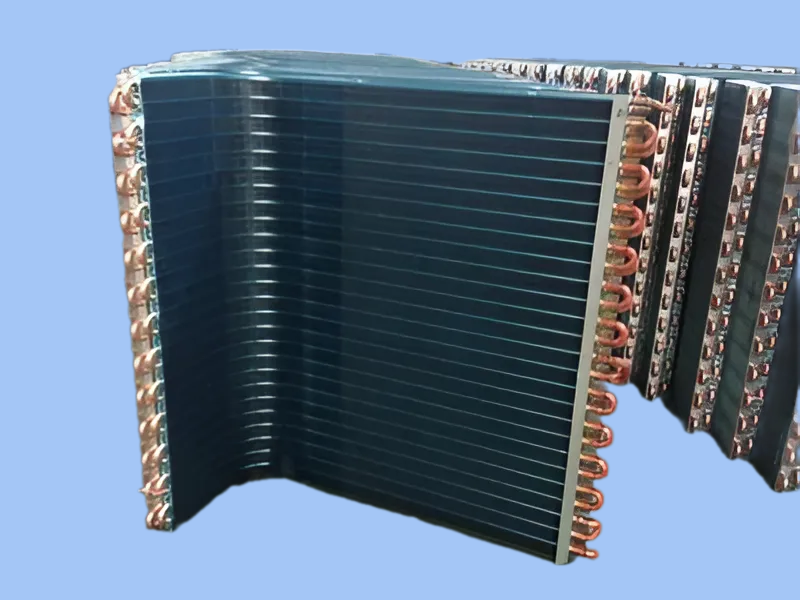

Testing Services for Finned Type Heat Exchangers for Room Air Conditioners – IS 11329:2018

Finned type heat exchangers are the backbone of efficient room air conditioning systems, directly impacting cooling performance, energy efficiency, and durability. At Absolute Veritas, we specialize in testing and certifying finned type heat exchangers to comply with IS 11329:2018, the Indian Standard governing the design, materials, and performance of these critical components. Our rigorous testing protocols ensure your heat exchangers meet stringent quality, safety, and efficiency benchmarks, empowering manufacturers to deliver reliable, high-performance air conditioning systems.

Why Choose Absolute Veritas Services for IS 11329:2018 Testing?

-

Only use NABL-Accredited Testing Labs in India: State-of-the-art labs equipped with advanced HVAC testing technologies.

-

Full Compliance: Testing aligned with IS 11329:2018 compliance testing and global standards.

-

Custom Solutions: Tailored testing for copper/aluminum finned tubes, microchannel heat exchangers, and more.

-

Speed & Accuracy: Fast turnaround with detailed, actionable reports.

Key Tests as per IS 11329:2018

The standard specifies critical evaluations for finned type heat exchangers. Our services include:

-

Thermal Performance Testing: Measures heat transfer efficiency under varying load conditions.

-

Pressure Testing: Validates structural integrity under high-pressure conditions.

-

Material & Corrosion Resistance: Evaluates corrosion resistance of fins, tubes, and joints in saline/humid environments.

-

Fin Bonding Strength: Tests adhesion between fins and tubes under mechanical stress.

-

Airflow Resistance Testing: Measures pressure drop across the heat exchanger to optimize airflow efficiency.

-

Refrigerant Leakage Test: Ensures leak-proof joints and connections using helium mass spectrometry or nitrogen testing.

-

Vibration & Durability Testing: Simulates long-term operational stress to assess fatigue resistance.

-

Salt Spray Testing: Validates corrosion resistance in coastal or high-humidity environments (e.g., ASTM B117).

-

Hydrophilic Coating Efficiency: Tests moisture absorption and drainage to prevent frost buildup.

-

Dimensional Accuracy: Verifies tube spacing, fin pitch, and alignment as per design specifications.

Compliance with IS 11329:2018 Requirements

The standard mandates:

-

Material Quality: Use of corrosion-resistant, non-toxic materials (e.g., copper tubes, aluminum fins).

-

Design Specifications: Optimal fin density, tube diameter, and airflow design

-

Performance Thresholds: Minimum heat transfer efficiency, pressure tolerance, and leakage limits.

-

Safety & Reliability: Structural integrity under operational stress and environmental exposure. (Safety Testing)

-

Documentation: Detailed technical specifications, test reports, and compliance certificates. (Bis Approved testing Lab India)

Additional Standards & Testing Consultancy Scope

Our services extend to related benchmarks, including:

-

IS 1391(PART 1):2023 : Room air conditioners performance testing.

-

IS 1391(PART 2):2023 : Performance testing for split air conditioners..

-

IS 8148: 2018 : Testing for ducted and packaged air conditioners.

-

IS 10617:2018 : Performance testing for hermetic compressors.

-

BEE Star Rating : Energy efficiency compliance for HVAC systems.

Why Finned Heat Exchanger Testing Matters

-

Energy Efficiency: Optimizes cooling capacity and reduces power consumption.

-

Longevity: Identifies material weaknesses to prevent premature failure.

-

Safety: Ensures leak-proof refrigerant circuits and electrical safety.

-

Market Compliance: Mandatory for BIS certification and consumer trust in India.

Why choose Absolute Veritas for Heat Exchangers testing in India?

Whether you’re a manufacturer, supplier, or importer, looking for IS 11329 Testing Lab in India our IS 11329:2018 testing and consulting services ensure your finned heat exchangers meet the highest standards of quality and reliability. From prototype validation to batch testing, we support you with:

-

Pre-certification testing for BIS approval.

-

Failure analysis to resolve production flaws.

-

Performance benchmarking against competitors.

-

Custom test setups for innovative designs.

Contact us today at cs@absoluteveritas.com to schedule air conditioner testing and ensure your heat exchangers deliver unmatched performance and compliance.

❮

❮