Tel: 0129-4001010 Phone: +91 730 321 5033

Email: cs@absoluteveritas.com

Comprehensive Guide to BIS Certification for Chipboard Screws Under IS 18508

INTRODUCTION

Chipboard screws are crucial for the woodworking and furniture industries, offering reliable fastening solutions for materials like wood panels and thin steel plates. These self-tapping screws streamline the process by creating their own threads during installation, eliminating the need for pre-tapping holes. Simply drive them in for a secure hold. However, the quality of these screws is vital, and that's where the Bureau of Indian Standards (BIS) IS 18508 standard becomes essential. Discover how Absolute Veritas can assist manufacturers in obtaining BIS certification to ensure their chipboard screws meet these important standards.

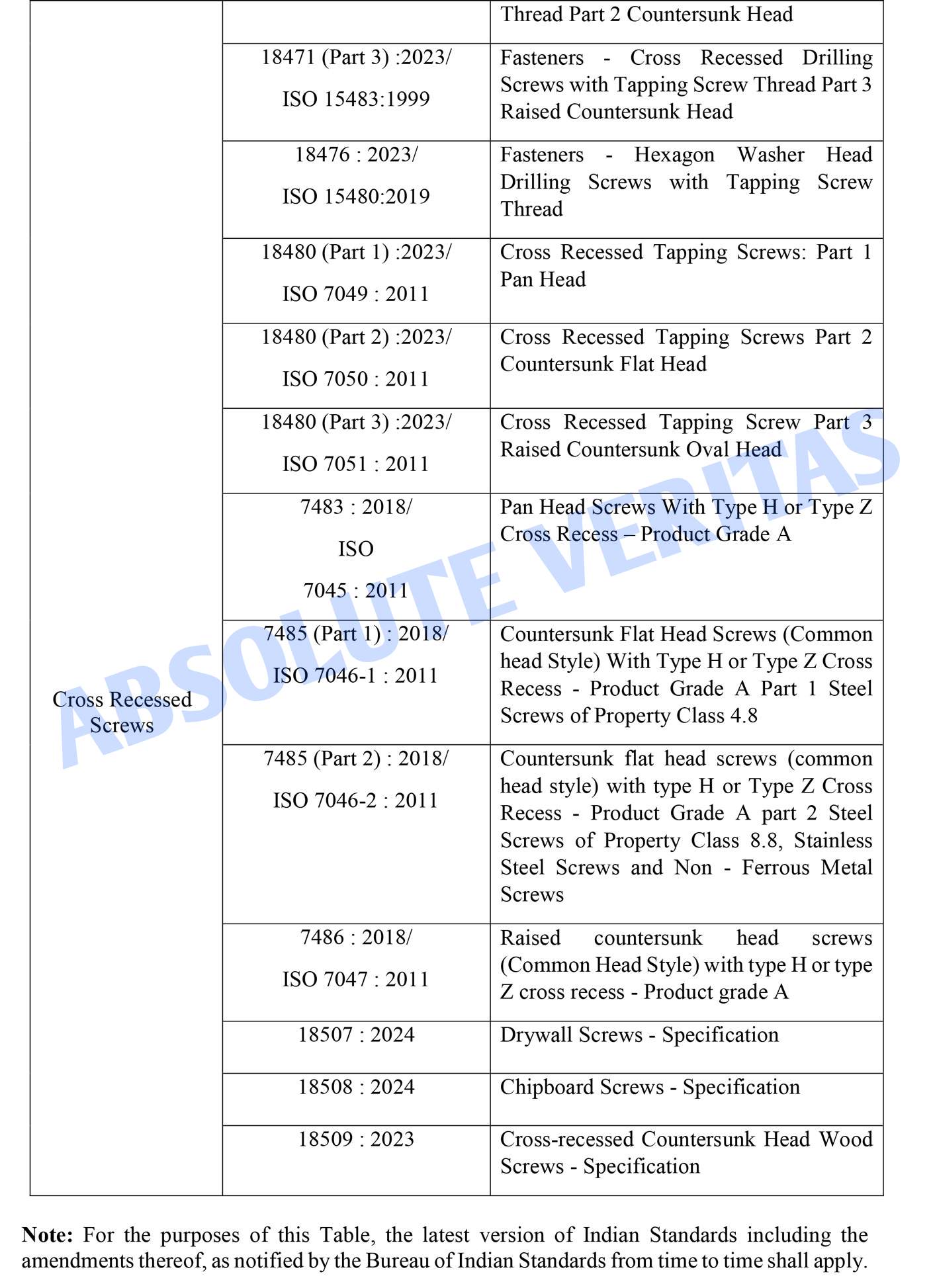

INDIAN STANDARD IS 18508

IS 18508 defines the specifications for cross-recessed chipboard screws with threaded diameters ranging from 3 mm to 6 mm. These screws are essential for fastening wood panels and thin metal sheets, making them vital in the furniture and construction industries.

Key aspects of IS 18508 include:

-

Dimensions and Tolerances: The standard specifies exact dimensions for cross-recessed chipboard screws and sets tolerances for length and thread depth.

-

Material Specifications: Screws can be made from steel, stainless steel, or brass, each with specific grades and requirements.

-

Surface Coating: Options include electroplating, phosphating, or other coatings, as agreed upon between the supplier and purchaser.

-

Surface and Core Hardness: Minimum requirements are set for surface hardness (320 HV 0.1) and core hardness (300 HV 0.5 to 450 HV 0.5).

-

Torque Testing: The standard mandates compliance with minimum breaking torque requirements to ensure performance.

-

Torque Testing: The standard mandates compliance with minimum breaking torque requirements to ensure performance.

Understanding these specifications helps ensure chipboard screws meet industry standards and deliver reliable performance in various applications.

DRAFT QUALITY CONTROL ORDER

The Department for Promotion of Industry and Internal Trade (DPIIT), under the Ministry of Commerce & Industry, Government of India, has proposed a draft Quality Control Order that mandates BIS certification for drywall screws. This requirement applies to both domestically manufactured and imported products, necessitating the ISI Mark under a valid BIS license.

BIS CERTIFICATION FOR IS 18508

BIS offers a certification scheme that ensures fasteners meet Indian standards. This process involves comprehensive evaluation and testing of products to confirm their adherence to specified standards. Once a product successfully passes this assessment, BIS issues certification, signaling its quality and compliance with regulatory requirements. This certification acts as a mark of reliability and trust, boosting market acceptance and competitiveness for certified products.

The certification process under IS 18508 is detailed and rigorous, covering critical aspects such as chemical composition, particle size, and other key parameters. For manufacturers, obtaining BIS certification is more than just meeting compliance; it reflects their dedication to quality, reliability, and excellence. However, navigating this certification process can be complex, demanding a thorough understanding of the standards and meticulous preparation.

EXPERT GUIDANCE FROM ABSOLUTE VERITAS

Absolute Veritas offers comprehensive support for BIS certification, assisting manufacturers with:

-

Application Submission: Ensuring all applications are complete and accurate.

-

Factory Inspection: Preparing for BIS inspections through effective quality control.

-

Sample Testing: Coordinating with BIS labs to confirm compliance.

-

Grant of Licence:Facilitating certification upon successful testing.

For Foreign manufacturers, Absolute Veritas provides:

-

Nominating Authorized Indian Representatives

-

Signing Agreements: Drafting and executing necessary BIS agreements.

-

Performance Bank Guarantees

-

Regular Monitoring: Conducting audits to ensure continuous compliance.

BENEFITS OF CHOOSING ABSOLUTE VERITAS

Partnering with Absolute Veritas

-

Expertise: Extensive regulatory knowledge.

-

Time and Cost Savings: Streamlined certification processes.

-

Performance Bank Guarantees

-

Assurance of Compliance: Reduced risk of rejection.

-

Continuous Support: Ongoing assistance for maintaining compliance.

CONCLUSION

Achieving BIS certification for chipboard screws under IS 18508 is essential for manufacturers looking to position their products as reliable and high-quality. This certification guarantees compliance with national standards, boosting consumer confidence and enhancing market competitiveness. Absolute Veritas plays a crucial role in this process by offering expert guidance and comprehensive support to help manufacturers navigate the certification process effectively. As the demand for superior fastening solutions rises, adherence to IS 18508 and obtaining BIS certification are fundamental to maintaining industry excellence.

WHY USE ABSOLUTE VERITAS (AV) FOR ISI MARK CERTIFICATION?

Absolute Veritas is a prominent organisation from the private sector of India primarily dealing with the Inspection, Testing, Audits, Certification of products& consulting services to various industries in India and worldwide, ensuring compliance with regulatory standards and industry requirements. Offering a comprehensive range of services including product certification, testing, training, auditing, and compliance services, Absolute Veritas helps manufacturers and importers achieve higher production efficiency and quality standards.

Absolute Veritas (AV) will handle end to end pre-registration request, sample preparation, documentation, testing and application process for ISI Mark Certification

For any questions regarding the most recent update on ISI registration licenses, please reach out to us via email at cs@absoluteveritas.com

❮

❮