Tel: 0129-4001010 Phone: +91 730 321 5033

Email: cs@absoluteveritas.com

BIS CERTIFICATION FOR TRANSPARENT FLOAT GLASS IS 14900:2018

In today's competitive landscape, maintaining market presence without a certified, high-quality product can be challenging. Obtaining a BIS license may also be essential for selling products in the Indian market. To achieve BIS certification and ensure product quality, manufacturers must adhere to the specified Indian standards.

Lets delve deeper into IS 14900:2018 for transparent float glass.

Transparent float glasses fall under the purview of IS 14900:2018. This Indian Standard was adopted by the Bureau of Indian Standards subsequent to the approval of the final draft by the Glassware Sectional Committee within the Chemical Division Council.

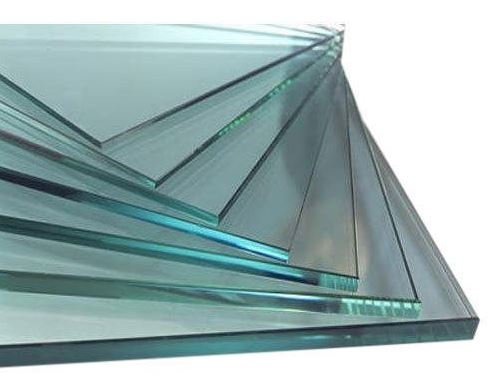

This standard delineates the specifications, sample, and testing procedures for flat, transparent, clear float glass characterized by glossy, plain, and smooth surfaces. It encompasses cut sizes or stock sheets available in square, rectangular, or other configurations. However, it's important to note that this standard excludes tinted, coated, frosted, heat-absorbing, or low-light-reducing glasses.

Float glass production involves the passage of molten glass from a tank furnace through a bath of molten tin, within a controlled atmosphere of nitrogen and hydrogen. This process yields a transparent glass sheet with flat and parallel surfaces, ensuring clear, undistorted vision and reflection. Thickness measurement should follow the guidelines outlined in Annex A. For cut sizes, glass length and width measurements must adhere to Annex B of the standard. Thickness tolerances should align with the standard's specifications, while length and width tolerances for cut sizes must also comply with the standard's requirements.

TESTS

The subsequent test must be conducted for Transparent Float Glass.

-

Characteristic

-

Visual light transmission

-

Dimension and tolerances

-

Optical faults

-

Visual faults

-

Bloom

Float glass should be carefully packed with shock-absorbing material and further enclosed in wooden cases for protection during transportation. Each package of float glass should prominently display the necessary information specified in the standard. Adhering to the guidelines of IS 14900:2018, the product may qualify for certification under the Bureau of Indian Standards Act, 2016, and its corresponding regulations, allowing it to bear the prestigious Standard Mark (ISI Mark). Manufacturers are required to secure a BIS license from the Bureau of Indian Standards to utilize the standard mark (ISI Mark), with the issuance contingent upon a successful evaluation of manufacturing infrastructure, quality control protocols, testing capabilities, and production processes.

PROCESS FOR BIS ISI MARK CERTIFICATION

BIS CERTIFICATION PROCESS

Acquiring a BIS license requires a comprehensive review of manufacturing infrastructure, quality control abilities, testing resources, and production procedures. This thorough assessment guarantees that products not only adhere to regulations but also prioritize consumer safety and reliability.

NOTE:

For comprehensive guidance on the BIS ISI Certification process, please explore:

WHY USE ABSOLUTE VERITAS?

Absolute Veritas is a prominent organisation from the private sector of India primarily dealing with the Inspection, Testing, Audits, Certification of products& consulting services to various industries in India and worldwide, ensuring compliance with regulatory standards and industry requirements. Offering a comprehensive range of services including product certification, testing, training, auditing, and compliance services, Absolute Veritas helps manufacturers and importers achieve higher production efficiency and quality standards.

Absolute Veritas (AV) will handle end to end pre-registration request, sample preparation, documentation, testing and application process for FMCS Certification

For any questions regarding the most recent update on FMCS registration licenses, please reach out to us via email at cs@absoluteveritas.com