Tel: 0129-4001010 Phone: +91 730 321 5033

Email: cs@absoluteveritas.com

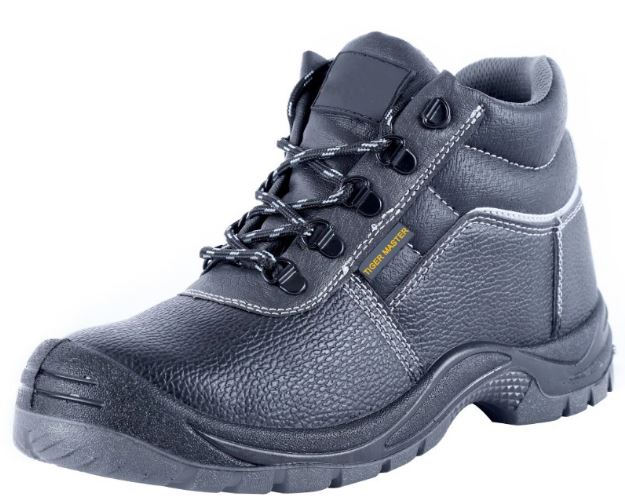

BIS CERTIFICATION FOR PERSONAL PROTECTIVE EQUIPMENT SAFETY FOOTWEAR IS 15298 (PART 2):2016

In today's competitive landscape, maintaining market presence without a certified, high-quality product can be challenging. Obtaining a BIS license may also be essential for selling products in the Indian market. To achieve BIS certification and ensure product quality, manufacturers must adhere to the specified Indian standards.

Lets delve deeper into IS 15298(Part 2):2016 for safety footwear.

Safety footwear falls under the purview of IS 15298(Part 2):2016. This standard outlines both fundamental and supplementary criteria for safety footwear.

Safety footwear is designed with protective elements to safeguard the wearer from potential injuries resulting from accidents. It includes toecaps and is crafted to shield against compression when subjected to a compression load of no less than 15 KN and against impact when tested with an energy level of at least 200 J.

Classification of footwear: Per the Indian Standard, footwear is categorized utilizing the subsequent code designations:

| Code designation | Classification |

|---|---|

| I | Footwear made from leather and other materials, excluding all-rubber or all-polymeric footwear. |

| II | All-rubber (i.e. entirely vulcanized) or all-polymeric (i.e. entirely moulded) footwear. |

Safety footwear must adhere to the fundamental criteria laid out in the Standard. It should comply with one of the designated designs specified in this specification. An insole, if present, must be securely fixed and not removable without causing harm to the footwear. Toecaps must be an integral part of the footwear construction, not detachable. Depending on workplace hazards, additional specifications for safety footwear may be necessary. In such cases, safety footwear must satisfy the extra criteria and corresponding markings as delineated in the Standard.

A well-equipped and adequately staffed laboratory should be maintained, where different tests will be conducted following the methods outlined in the specification.

TESTS

The subsequent test must be conducted for safety footwear.

-

Upper and outsole bond strength test

-

Compression resistance test

-

Leak proof test

-

Tear strength test

-

Tensile properties test

-

Flexing resistance test

-

Water vapor permeability

-

Hydrolysis test

-

Abrasion resistance test

The ISI Mark must be affixed to every piece of safety footwear and the outer packaging for each pair, provided that the footwear meets all the requirements outlined in the specification. All markings should be placed inside the tongue or on the top outer face of the boot to minimize damage during use. Additionally, each safety footwear item must be clearly and permanently labeled with the information specified in the Standard. Manufacturers are required to obtain a BIS license from the Bureau of Indian Standards to use the standard mark (ISI Mark), which is granted based on an evaluation of manufacturing infrastructure, quality control, testing capabilities, and production process.

PROCESS FOR BIS ISI MARK CERTIFICATION

BIS CERTIFICATION PROCESS

Acquiring a BIS license requires a comprehensive review of manufacturing infrastructure, quality control abilities, testing resources, and production procedures. This thorough assessment guarantees that products not only adhere to regulations but also prioritize consumer safety and reliability.

NOTE:

For comprehensive guidance on the BIS ISI Certification process, please explore:

WHY USE ABSOLUTE VERITAS?

Absolute Veritas is a prominent organisation from the private sector of India primarily dealing with the Inspection, Testing, Audits, Certification of products& consulting services to various industries in India and worldwide, ensuring compliance with regulatory standards and industry requirements. Offering a comprehensive range of services including product certification, testing, training, auditing, and compliance services, Absolute Veritas helps manufacturers and importers achieve higher production efficiency and quality standards.

Absolute Veritas (AV) will handle end to end pre-registration request, sample preparation, documentation, testing and application process for FMCS Certification

For any questions regarding the most recent update on FMCS registration licenses, please reach out to us via email at cs@absoluteveritas.com