Tel: 0129-4001010 Phone: +91 730 321 5033

Email: cs@absoluteveritas.com

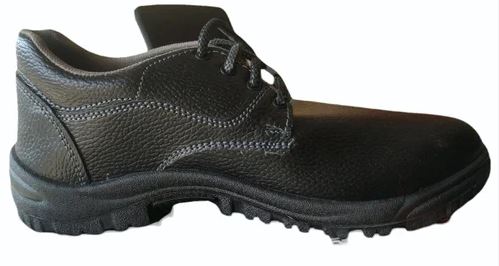

BIS CERTIFICATION FOR LEATHER SAFETY FOOTWEAR MOULDED PVC SOLE IS 14544:1998

In today's competitive landscape, maintaining market presence without a certified, high-quality product can be challenging. Obtaining a BIS license may also be essential for selling products in the Indian market. To achieve BIS certification and ensure product quality, manufacturers must adhere to the specified Indian standards.

Lets delve deeper into IS 14544:1998 for Leather Safety Footwear with Direct Moulded Polyvinyl Chloride (PVC) Sole.

Leather safety footwear featuring direct molded polyvinyl chloride (PVC) soles falls under IS 14544:1998. This Indian Standard was adopted by the Bureau of Indian Standards following the approval of the final draft by the Footwear Sectional Committee and the Chemical Division Council.

This standard pertains to leather safety boots and shoes equipped with direct molded polyvinyl chloride (PVC) soles, intended for industrial use with general-purpose oil and chemical resistance. It's worth noting that leather safety footwear with direct molded rubber soles is already covered by a separate Indian Standard, IS 11226:1993.

This standard outlines the specifications, testing procedures, and sampling methods for leather safety footwear featuring steel toe caps and direct molded soles predominantly made of PVC as the primary raw material.

Leather safety footwear with direct molded PVC soles shall be categorized into the following three types, based on their design:

-

Type 1 - General purpose safety shoes.

-

Type 2 - Safety shoes with oil-resistant soles.

-

Type 3 - Safety shoes with chemical resistant soles.

All varieties and styles of leather safety footwear must be crafted through direct molding using chrome-tanned upper leather. The soles and heels should feature a slip-resistant pattern for enhanced traction. The upper leather utilized must be full chrome leather, adhering to the specifications of IS 5677. The footwear production can employ either the direct molding process (DMP) or the direct injection process (DIP).

TESTS

The subsequent test must be conducted for Leather Safety Footwear with Direct Moulded Polyvinyl Chloride (PVC) Sole.

-

Performance test

-

Impact test

-

Adhesion Test on Moulded Bottoms

-

Breaking Strength test

If applicable, footwear sizes and trademarks should be integrated into the mold to ensure their legibility on the outer sole's waist. Additionally, the size and fitting number, along with the year of manufacture, must be clearly marked on the insole waist and the full sock. The product may also feature the Standard Mark (ISI Mark), and it must adhere to the packing specifications outlined in the standard. Manufacturers are required to obtain a BIS license from the Bureau of Indian Standards to utilize the standard mark (ISI Mark). This license is granted following a successful assessment of manufacturing infrastructure, quality control, and testing capabilities, conducted during a visit to the manufacturing premises.

PROCESS FOR BIS ISI MARK CERTIFICATION

BIS CERTIFICATION PROCESS

Acquiring a BIS license requires a comprehensive review of manufacturing infrastructure, quality control abilities, testing resources, and production procedures. This thorough assessment guarantees that products not only adhere to regulations but also prioritize consumer safety and reliability.

NOTE:

For comprehensive guidance on the BIS ISI Certification process, please explore:

WHY USE ABSOLUTE VERITAS?

Absolute Veritas is a prominent organisation from the private sector of India primarily dealing with the Inspection, Testing, Audits, Certification of products& consulting services to various industries in India and worldwide, ensuring compliance with regulatory standards and industry requirements. Offering a comprehensive range of services including product certification, testing, training, auditing, and compliance services, Absolute Veritas helps manufacturers and importers achieve higher production efficiency and quality standards.

Absolute Veritas (AV) will handle end to end pre-registration request, sample preparation, documentation, testing and application process for FMCS Certification

For any questions regarding the most recent update on FMCS registration licenses, please reach out to us via email at cs@absoluteveritas.com

❮

❮